| Availability: | |

|---|---|

| Quantity: | |

LS-450PLUS

Longxingsheng

Box Packing Machine For Rigid Box Making, Book Cover Making And Paper Lining. This machine is also called as gluing and spotter machine. It can finish paper gluing and pasting box on the glued paper automatically, which is widely used for rigid box making, book cover machine, paper lining and even album making.

LS-450plus is a multi-function visual positioning machine. It is able to positioning the rigid box and hardcover. also can do paper lining, one machine with many functions, and the working model is able to be changed by one button. The visual positioning system is able to be upgraded. Moreover, this machine also can be upgraded to an automatic line in the future if needed.

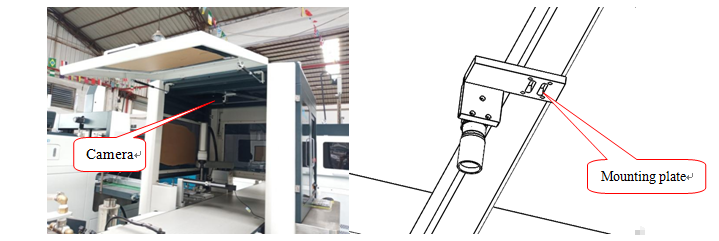

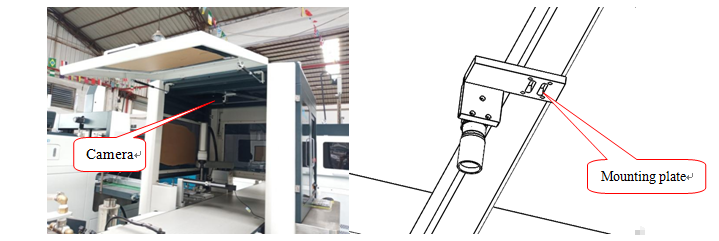

Equipped with dual cameras, the cameras are located on both sides of the central position of the conveyor belt. The camera position has been calibrated before leaving the factory. If there is any deviation, you can adjust the camera position by adjusting the upper camera "mounting plate". After the camera takes a picture, the system recognizes the color difference of the photo for positioning. If the surface paper and the surface paper conveyor belt are similar in color, it can be solved by changing the belt color.

5. Panasonic Servo motor feeding system.

Automatic production line suitable for all kinds of rigid box

Fault diagnosis function

Automatically sucking the cover paper and feeding the cardboard

High-precision cam feeding system

Panasonic servo control system

Visual positioning system and machine grasping

Using Yamaha Robot

Adopt a new cycle temperature control gluing system

Using high-definition camera positioning

Glue Viscosity Device: Automatic detecting the hot melt glue thickness.

Air Operated Double Diaphragm Pump: Applied in white glue pumping.

Bottom sucker hardcover feeding device: Special design for feeding hardcover, to avoid scraping hardcover.

| Type | LS-450puls |

| Paper size (max) | L800*W600mm |

| Paper size (min) | L135*W100mm |

| Box size (max) | L600*W400*H120mm |

| Box size (min) | L80*W65*H15mm |

| Hard cover (max) | L750*W450mm |

| Hard cover (min) | L150*W100mm |

| Paper thickness | 100-350g/㎡ |

| Paper stacking height | 450mm/100kg |

| Working speed | 15-45 sheet/min |

| Positioning accuracy | ±0.1mm |

| Motor power | 7.5kw/380v 3phase |

| Heating power | 8kw/380v 3phase |

| Air pressure | 10L/min 0.6MPa |

| Machine weight | 2100kg |

| Machine dimension | L5980*W3180*H2100mm |

Certificates: ISO9001-2008, Quality management system, CE certificate.

Mission & Vision: Provide smart modular for packaging.

Products scope: Automatic rigid box making machine. V grooving machine. Visual positioning machine. Rigid box former. Corner

pasting machine. Gluing machine and other machinery.

Market positioning: Middle and high-end market

1. Professional QC and QA team to make sure all products qualified before shipping.

2. Competitive price

3 .Standard package to ensure the safe transportation.

4. Professional service

Box Packing Machine For Rigid Box Making, Book Cover Making And Paper Lining. This machine is also called as gluing and spotter machine. It can finish paper gluing and pasting box on the glued paper automatically, which is widely used for rigid box making, book cover machine, paper lining and even album making.

LS-450plus is a multi-function visual positioning machine. It is able to positioning the rigid box and hardcover. also can do paper lining, one machine with many functions, and the working model is able to be changed by one button. The visual positioning system is able to be upgraded. Moreover, this machine also can be upgraded to an automatic line in the future if needed.

Equipped with dual cameras, the cameras are located on both sides of the central position of the conveyor belt. The camera position has been calibrated before leaving the factory. If there is any deviation, you can adjust the camera position by adjusting the upper camera "mounting plate". After the camera takes a picture, the system recognizes the color difference of the photo for positioning. If the surface paper and the surface paper conveyor belt are similar in color, it can be solved by changing the belt color.

5. Panasonic Servo motor feeding system.

Automatic production line suitable for all kinds of rigid box

Fault diagnosis function

Automatically sucking the cover paper and feeding the cardboard

High-precision cam feeding system

Panasonic servo control system

Visual positioning system and machine grasping

Using Yamaha Robot

Adopt a new cycle temperature control gluing system

Using high-definition camera positioning

Glue Viscosity Device: Automatic detecting the hot melt glue thickness.

Air Operated Double Diaphragm Pump: Applied in white glue pumping.

Bottom sucker hardcover feeding device: Special design for feeding hardcover, to avoid scraping hardcover.

| Type | LS-450puls |

| Paper size (max) | L800*W600mm |

| Paper size (min) | L135*W100mm |

| Box size (max) | L600*W400*H120mm |

| Box size (min) | L80*W65*H15mm |

| Hard cover (max) | L750*W450mm |

| Hard cover (min) | L150*W100mm |

| Paper thickness | 100-350g/㎡ |

| Paper stacking height | 450mm/100kg |

| Working speed | 15-45 sheet/min |

| Positioning accuracy | ±0.1mm |

| Motor power | 7.5kw/380v 3phase |

| Heating power | 8kw/380v 3phase |

| Air pressure | 10L/min 0.6MPa |

| Machine weight | 2100kg |

| Machine dimension | L5980*W3180*H2100mm |

Certificates: ISO9001-2008, Quality management system, CE certificate.

Mission & Vision: Provide smart modular for packaging.

Products scope: Automatic rigid box making machine. V grooving machine. Visual positioning machine. Rigid box former. Corner

pasting machine. Gluing machine and other machinery.

Market positioning: Middle and high-end market

1. Professional QC and QA team to make sure all products qualified before shipping.

2. Competitive price

3 .Standard package to ensure the safe transportation.

4. Professional service