| Availability: | |

|---|---|

| Quantity: | |

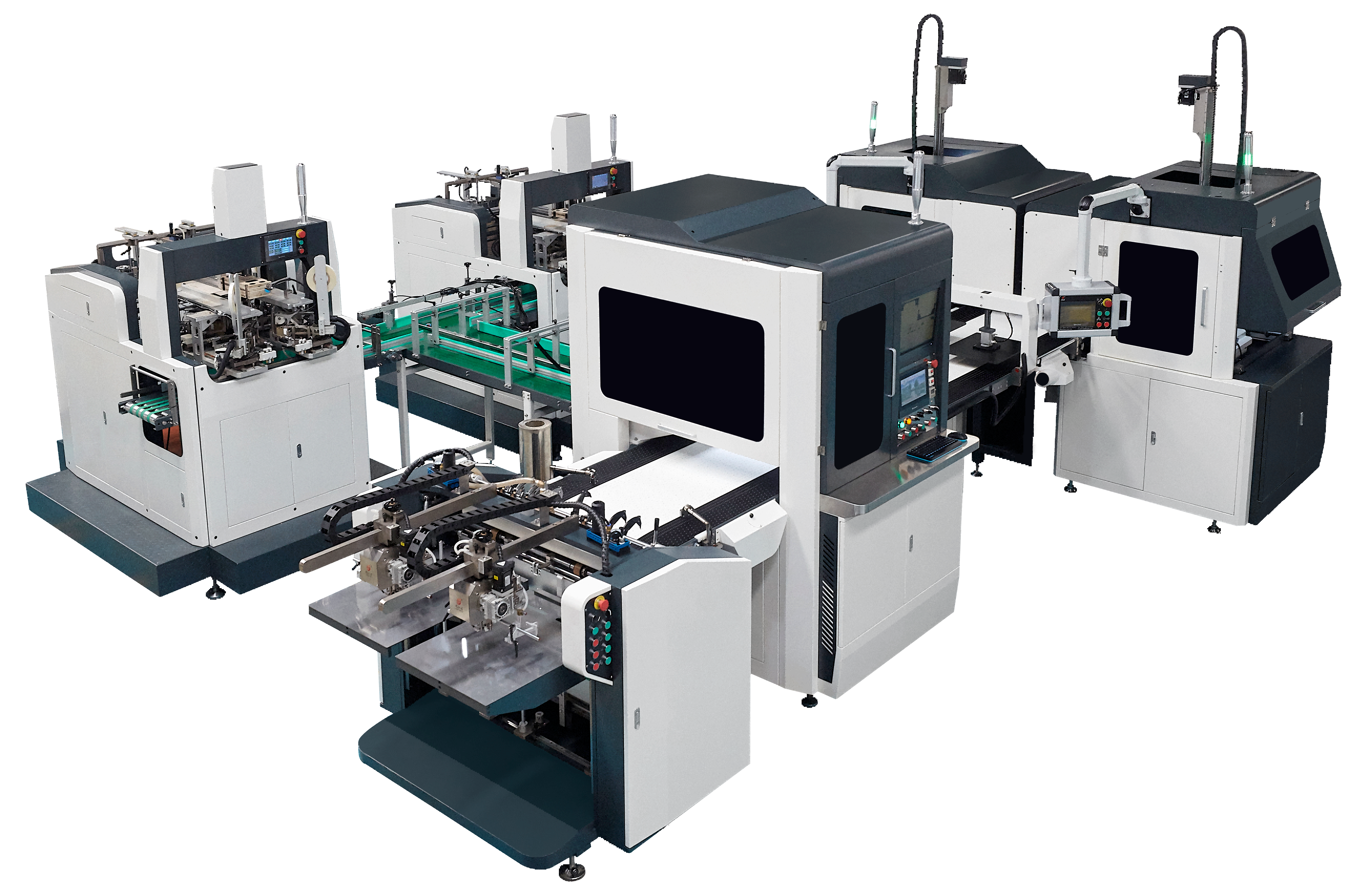

LS-900A

Longxingsheng

LS-900A

This professional grade machine is designed to simplify and enhance the box making process. With its advanced features and efficient functions, it is the perfect solution for both large and small orders.

The machine can make 25 pairs of boxes per minute, and the maximum size of the boxes that can be made is: 400*300*100mm. It is the fastest two-station world-lid box making machine on the market, and it is also the one with the largest box size. Duplex machine. The machine has double paper feeding system, double cardboard corner sticking machine, double forming parts, which ensure the high efficiency of machine operation

Experience the convenience and efficiency of the Fully Automatic Intelligent Rigid Box Making Machine. Its professional tone and robust features make it the ideal choice for businesses in need of high-quality box production.

Easy to operate: Longxingsheng Intelligent Rigid Box Making Machine is easy to operate, even for those with little experience in packaging production. The machine is equipped with a user-friendly interface, which is easy to learn, even those who have no operating experience can quickly learn to operate, so that the operator can easily set up and operate the machine, so that customers can rest assured and provide customers with protection in this regard.

This machine can help you make different kinds of boxes such as packaging boxes, gift boxes, display boxes, etc. Suitable for large and small orders, suitable for various rigid box manufacturers

1. Paper loading part: Double feeding platform by separated control

2. Feeding system:Automatic cycle feeding by feeder

3. Belt adjustment system: non-stop belt adjustment

4. Gluing system:: Integrated gluing guide groove, easy to clean

5. Paper feeding part: Servo-driven cam feeder effectively avoids double paper feeding.

6.computer control: Servo control digital quick size adjustment

8. Box positioning system: big size range positioning, various in application, single mode running available.

Second pressing to make the bottom of the box stick better

Adopt black and white belt for more color application

Robotic arm: High accuracy ± 0.1mm

Using double cameras to operate independently, high speed and clear photo taking.

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | / |

| Min cardboard size | / |

| Box size(Length) | L50-350mm |

| Box size(Width) | W50-250mm |

| Box size(Height) | H10-120mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-5mm |

| Edge folding size | / |

| Turn in depth | 15-80mm |

| Motor power | 9kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 30L/min |

| Machine dimension | L6378xW3860xH2200mm |

| Weight of machine | 2300kg |

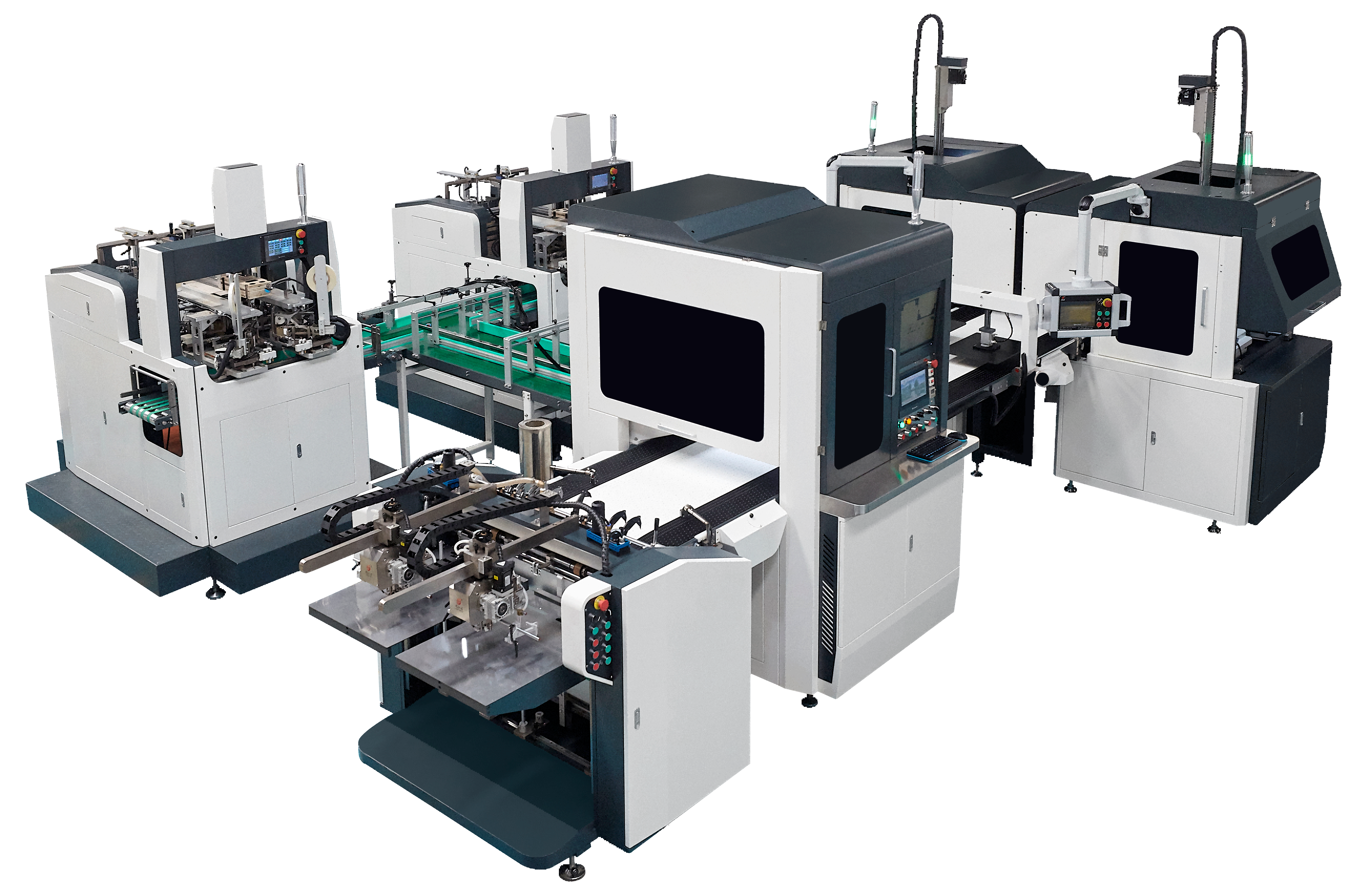

LS-900A

This professional grade machine is designed to simplify and enhance the box making process. With its advanced features and efficient functions, it is the perfect solution for both large and small orders.

The machine can make 25 pairs of boxes per minute, and the maximum size of the boxes that can be made is: 400*300*100mm. It is the fastest two-station world-lid box making machine on the market, and it is also the one with the largest box size. Duplex machine. The machine has double paper feeding system, double cardboard corner sticking machine, double forming parts, which ensure the high efficiency of machine operation

Experience the convenience and efficiency of the Fully Automatic Intelligent Rigid Box Making Machine. Its professional tone and robust features make it the ideal choice for businesses in need of high-quality box production.

Easy to operate: Longxingsheng Intelligent Rigid Box Making Machine is easy to operate, even for those with little experience in packaging production. The machine is equipped with a user-friendly interface, which is easy to learn, even those who have no operating experience can quickly learn to operate, so that the operator can easily set up and operate the machine, so that customers can rest assured and provide customers with protection in this regard.

This machine can help you make different kinds of boxes such as packaging boxes, gift boxes, display boxes, etc. Suitable for large and small orders, suitable for various rigid box manufacturers

1. Paper loading part: Double feeding platform by separated control

2. Feeding system:Automatic cycle feeding by feeder

3. Belt adjustment system: non-stop belt adjustment

4. Gluing system:: Integrated gluing guide groove, easy to clean

5. Paper feeding part: Servo-driven cam feeder effectively avoids double paper feeding.

6.computer control: Servo control digital quick size adjustment

8. Box positioning system: big size range positioning, various in application, single mode running available.

Second pressing to make the bottom of the box stick better

Adopt black and white belt for more color application

Robotic arm: High accuracy ± 0.1mm

Using double cameras to operate independently, high speed and clear photo taking.

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | / |

| Min cardboard size | / |

| Box size(Length) | L50-350mm |

| Box size(Width) | W50-250mm |

| Box size(Height) | H10-120mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-5mm |

| Edge folding size | / |

| Turn in depth | 15-80mm |

| Motor power | 9kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 30L/min |

| Machine dimension | L6378xW3860xH2200mm |

| Weight of machine | 2300kg |