| Availability: | |

|---|---|

| Quantity: | |

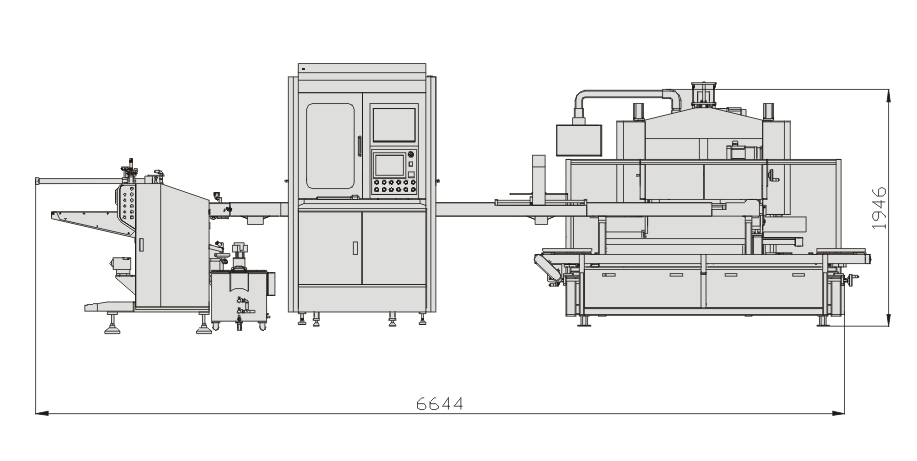

LS-300B

Longxingsheng

Launched the fully automatic intelligent hard cover box manufacturing machine. This professional grade machine is designed to simplify and enhance the box making process. With its advanced features and efficient functions, it is the perfect solution for both large and small orders.

This machine adopts visual positioning, simple positioning and high precision. The molding station is automatically set, which greatly reduces the setting time. whole machine. The entire line setup time is 45-60 minutes. The box making speed of this machine can reach 45 pcs/min. This can meet different order quantity requirements. What's more, it has the smallest working size. Styler can help you get more orders.

1. Gluing part(paper gluing):The paper is separated into single sheet, the glue is evenly coated on the face paper

through the roller, and then the glued face paper is transported to the box positioning part by the conveyor belt.

2. Positioning part(box positioning):Grab the box by robotic arm, and position it on the glued paper by camera.

3. Forming part(box forming):Finish wrapping four sides and air pressing of box after positioning, and finally move

the finished boxes out of the production line from both sides of the machine.

4.Corner pasting machine:Feeding conveys the cardboard to the corner pasting machine, and the corner pasting machine automatically recognizes and presses down the mold, and at the same time, the four stickers at the four corners and the appropriate adhesive tape stick to the four corners of the gray board to quickly shape the card- board, and then the conveyor belt output to the positioning unit.

1. Suitable for all kinds of automatic production line

2. Troubleshooting

3. Automatic suction, paper and cardboard feeding

4. High precision CAM paper feeding

5. Panasonic servo control system

6. Visual positioning system and robot grasp (positioning error less than 0.1mm)

7. Yamaha robotic arm

8. New cycle temperature control gluing system

9. Precise four-angle box holding robot

10. Precise sliding table folding, folding length can be adjusted

11. Built-in constant temperature system (optional)

12. HD camera positioning

Paper gluing&Cardboard corner pasting --Cardboard box positioning--box forming

| Type | LS-300B |

| Paper size (max) | L800 * W600mm |

| Paper size (min) | L135 * W100mm |

| Cardboard size (max) | L760 * W560mm |

| Cardboard size (min) | L400 * W300 * H100mm |

| Box size (max) | L80 * W60 * H15mm |

| Cartoon paper thickness | 100-350g/㎡ |

| Cardboard thickness | 0.8-3mm |

| Edge folding size | 10-90mm |

| Tuin in depth | 15-80mm |

| Air pressure | 40L/min 0.8MPa |

| Working speed | 15-35 pcs/min |

| Motor power | 14kw/380v 3 phase |

| Heating power | 8kw |

| Weights | 5100kg |

| Dimension | L6600 * W3800 * H3000mm |

This machine is suitable for all kinds of rigid box making.It is good idear for box making manufacturer.

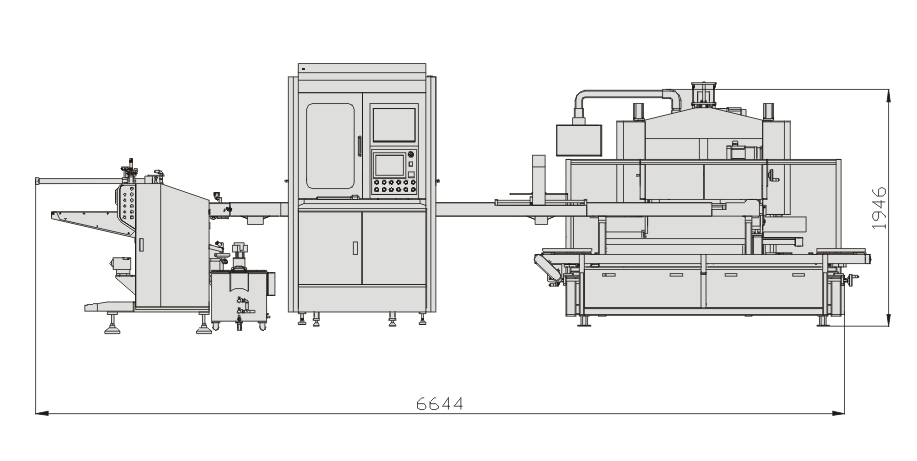

Launched the fully automatic intelligent hard cover box manufacturing machine. This professional grade machine is designed to simplify and enhance the box making process. With its advanced features and efficient functions, it is the perfect solution for both large and small orders.

This machine adopts visual positioning, simple positioning and high precision. The molding station is automatically set, which greatly reduces the setting time. whole machine. The entire line setup time is 45-60 minutes. The box making speed of this machine can reach 45 pcs/min. This can meet different order quantity requirements. What's more, it has the smallest working size. Styler can help you get more orders.

1. Gluing part(paper gluing):The paper is separated into single sheet, the glue is evenly coated on the face paper

through the roller, and then the glued face paper is transported to the box positioning part by the conveyor belt.

2. Positioning part(box positioning):Grab the box by robotic arm, and position it on the glued paper by camera.

3. Forming part(box forming):Finish wrapping four sides and air pressing of box after positioning, and finally move

the finished boxes out of the production line from both sides of the machine.

4.Corner pasting machine:Feeding conveys the cardboard to the corner pasting machine, and the corner pasting machine automatically recognizes and presses down the mold, and at the same time, the four stickers at the four corners and the appropriate adhesive tape stick to the four corners of the gray board to quickly shape the card- board, and then the conveyor belt output to the positioning unit.

1. Suitable for all kinds of automatic production line

2. Troubleshooting

3. Automatic suction, paper and cardboard feeding

4. High precision CAM paper feeding

5. Panasonic servo control system

6. Visual positioning system and robot grasp (positioning error less than 0.1mm)

7. Yamaha robotic arm

8. New cycle temperature control gluing system

9. Precise four-angle box holding robot

10. Precise sliding table folding, folding length can be adjusted

11. Built-in constant temperature system (optional)

12. HD camera positioning

Paper gluing&Cardboard corner pasting --Cardboard box positioning--box forming

| Type | LS-300B |

| Paper size (max) | L800 * W600mm |

| Paper size (min) | L135 * W100mm |

| Cardboard size (max) | L760 * W560mm |

| Cardboard size (min) | L400 * W300 * H100mm |

| Box size (max) | L80 * W60 * H15mm |

| Cartoon paper thickness | 100-350g/㎡ |

| Cardboard thickness | 0.8-3mm |

| Edge folding size | 10-90mm |

| Tuin in depth | 15-80mm |

| Air pressure | 40L/min 0.8MPa |

| Working speed | 15-35 pcs/min |

| Motor power | 14kw/380v 3 phase |

| Heating power | 8kw |

| Weights | 5100kg |

| Dimension | L6600 * W3800 * H3000mm |

This machine is suitable for all kinds of rigid box making.It is good idear for box making manufacturer.