| Availability: | |

|---|---|

| Quantity: | |

LS-1200C

longxingsheng

Launched a fully automatic, high-speed, high-efficiency, dust-free cardboard density board slotting machine. This professional-grade machine is specially designed for the production of various box materials such as gray board, cardboard, density board, etc.

The machine has a built-in alignment system that ensures precise grooving for a perfect final product. The machine is equipped with a waste separation system that can separate finished products and waste materials for efficient transportation.

The machine features adjustable upper and lower cutting heads ranging from 80° to 140°, providing flexibility for creating custom slot designs. Its dual workstation feeding system further increases productivity, doubling output and thus increasing efficiency.

Invest in an automatic high-speed, high-efficiency dust-free cardboard MDF slotting machine to meet your manufacturing needs. Experience professional-grade performance and achieve outstanding results with this reliable and versatile machine.

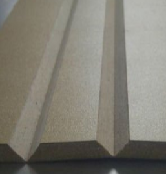

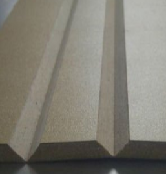

One of the biggest advantages of two-V machines is their accuracy. This machine is designed for precision cuts, which means you’ll create clean, straight edges every time. This is useful when working with materials such as colored boards and papers that are difficult to cut properly and so on.

Blade seats are consists of high accuracy sliding block and rotion gear wheel, make operation easier.

Narrow and wide belts ensures setting any grooving position.Suiteable for more products.

Paper feeding aligning system

Machine model | LS-1200C |

Grooving blade quantity | 4 |

Working speed | 35m/min(100-200pcs/min) |

Cardboard size | 140*120-600*600mm |

Cardboard thickness | 0.5-4mm |

Carton paper thickness | 500-800g/m2 |

Blade material | Tungsten steel |

Grooving speed | 100-130PCS |

Grooving Blade type | V grooving |

Min grooving gap (between two grooves) | 0 (2 lines blade design) |

Motor power | 4.5 kw/380v 3 phase |

Machine dimension | L2050*W1320*H1350mm |

Machine weight | 3520kg |

For any packaging manufacturer looking to increase production capacity, investing in an automatic high-speed cartonboard MDF slotting machine is a wise choice. With its cutting-edge technology, versatility and user-friendly interface, it provides a competitive edge in a rapidly evolving industry. By automating the grooving process, manufacturers can significantly increase production, reduce costs and consistently deliver high-quality products to customers.

Launched a fully automatic, high-speed, high-efficiency, dust-free cardboard density board slotting machine. This professional-grade machine is specially designed for the production of various box materials such as gray board, cardboard, density board, etc.

The machine has a built-in alignment system that ensures precise grooving for a perfect final product. The machine is equipped with a waste separation system that can separate finished products and waste materials for efficient transportation.

The machine features adjustable upper and lower cutting heads ranging from 80° to 140°, providing flexibility for creating custom slot designs. Its dual workstation feeding system further increases productivity, doubling output and thus increasing efficiency.

Invest in an automatic high-speed, high-efficiency dust-free cardboard MDF slotting machine to meet your manufacturing needs. Experience professional-grade performance and achieve outstanding results with this reliable and versatile machine.

One of the biggest advantages of two-V machines is their accuracy. This machine is designed for precision cuts, which means you’ll create clean, straight edges every time. This is useful when working with materials such as colored boards and papers that are difficult to cut properly and so on.

Blade seats are consists of high accuracy sliding block and rotion gear wheel, make operation easier.

Narrow and wide belts ensures setting any grooving position.Suiteable for more products.

Paper feeding aligning system

Machine model | LS-1200C |

Grooving blade quantity | 4 |

Working speed | 35m/min(100-200pcs/min) |

Cardboard size | 140*120-600*600mm |

Cardboard thickness | 0.5-4mm |

Carton paper thickness | 500-800g/m2 |

Blade material | Tungsten steel |

Grooving speed | 100-130PCS |

Grooving Blade type | V grooving |

Min grooving gap (between two grooves) | 0 (2 lines blade design) |

Motor power | 4.5 kw/380v 3 phase |

Machine dimension | L2050*W1320*H1350mm |

Machine weight | 3520kg |

For any packaging manufacturer looking to increase production capacity, investing in an automatic high-speed cartonboard MDF slotting machine is a wise choice. With its cutting-edge technology, versatility and user-friendly interface, it provides a competitive edge in a rapidly evolving industry. By automating the grooving process, manufacturers can significantly increase production, reduce costs and consistently deliver high-quality products to customers.