| Availability: | |

|---|---|

| Quantity: | |

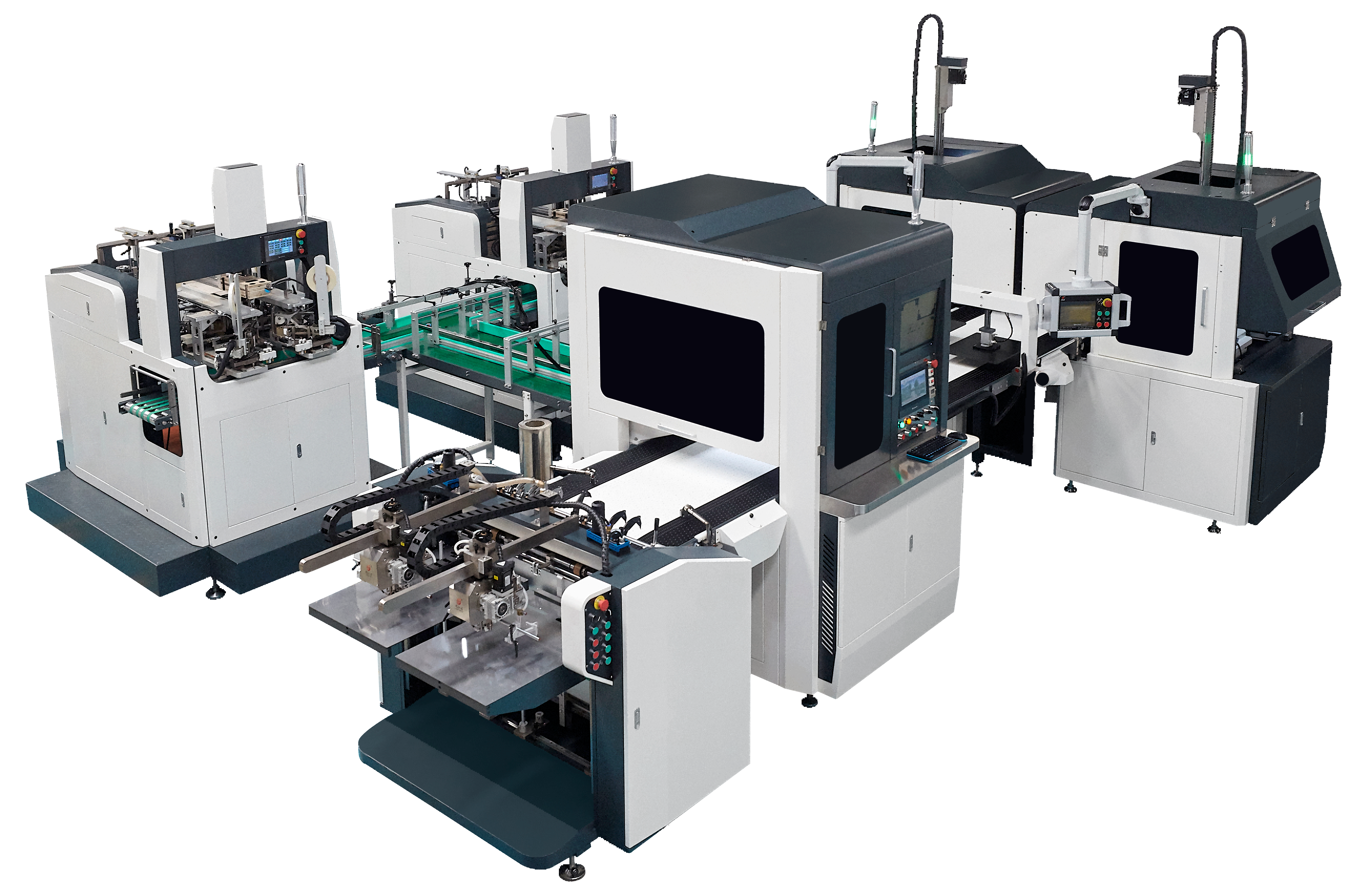

LS-900A

Longxingsheng

Enhance your cardboard lamination production process with our state-of-the-art Automatic Double Duty Rigid Box Making Machine. Specifically designed for manufacturers in need of efficient and versatile equipment, this cutting-edge machine combines advanced technology with precision engineering to streamline your production and deliver outstanding results.

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | / |

| Min cardboard size | / |

| Box size(Length) | L50-350mm |

| Box size(Width) | W50-250mm |

| Box size(Height) | H10-120mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-5mm |

| Edge folding size | / |

| Turn in depth | 15-80mm |

| Motor power | 9kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 30L/min |

| Machine dimension | L6378xW3860xH2200mm |

| Weight of machine | 2300kg |

Powered by Mitsubishi servo motors and PLC servo motors, this machine delivers exceptional performance and reliability. The inclusion of a high-precision YAMAHA robotic arm further enhances the efficiency and stability of box production. With a production capacity of 12-25 pairs of boxes per minute, this machine is capable of meeting the demands of large-scale orders. Additionally, its adjustable speed feature makes it suitable for smaller orders as well.

Key Features:

Dual Functionality: Our Automatic Double Duty Rigid Box Making Machine offers dual functionality, allowing you to laminate cardboard and manufacture rigid boxes in a single, seamless process. This versatile feature eliminates the need for multiple machines and optimizes your production line for enhanced efficiency and productivity.

High-Quality Lamination: Achieve impeccable cardboard lamination with this advanced machine. Its precision rollers and adjustable settings ensure uniform and smooth lamination, resulting in visually appealing and durable cardboard sheets. Experience consistent quality and excellent adhesion for your rigid box production.

Efficient Box Making: Seamlessly transition from cardboard lamination to rigid box production with ease. This machine automates the box-making process, from folding to gluing, ensuring precise and flawless box construction. Increase your production capacity and reduce manual labor, saving valuable time and resources.

Customizable Box Sizes: Cater to a wide range of packaging needs with the Automatic Double Duty Rigid Box Making Machine. It accommodates various box sizes and styles, allowing you to create customized packaging solutions tailored to your specific requirements. From small gift boxes to large display cases, this machine offers unparalleled flexibility.

User-Friendly Operation: Simplify your production process with the machine's user-friendly interface. The intuitive control panel and clear instructions make it easy for operators to navigate and operate the machine efficiently. Minimize training time and maximize productivity with this user-centric design.

Robust and Reliable: Built to withstand the demands of industrial production, our Automatic Double Duty Rigid Box Making Machine is constructed with high-quality materials and components. Its robust design ensures durability and long-term reliability, providing you with a dependable solution that delivers consistent results.

1. Paper loading part: Double feeding platform by separated control

2. Feeding system:Automatic cycle feeding by feeder

3. Belt adjustment system: non-stop belt adjustment

4. Gluing system: Integrated gluing guide groove, easy to clean

5. Paper feeding part: Servo-driven cam feeder effectively avoids double paper feeding.

6.computer control: Servo control digital quick size adjustment

8. Box positioning system: big size range positioning, various in application, single mode running available.

Second pressing to make the bottom of the box stick better

Adopt black and white belt for more color application

Robotic arm: High accuracy ± 0.1mm

Using double cameras to operate independently, high speed and clear photo taking.

Whether you manufacture gift boxes, jewelry boxes, or premium product packaging, our Automatic Multi-functional Rigid Box Making Machine caters to your needs, adding unique value and appeal to your products.

Contact us now to learn more about the Automatic Multi-functional Rigid Box Making Machine and let us assist you in creating exquisite rigid box covers!

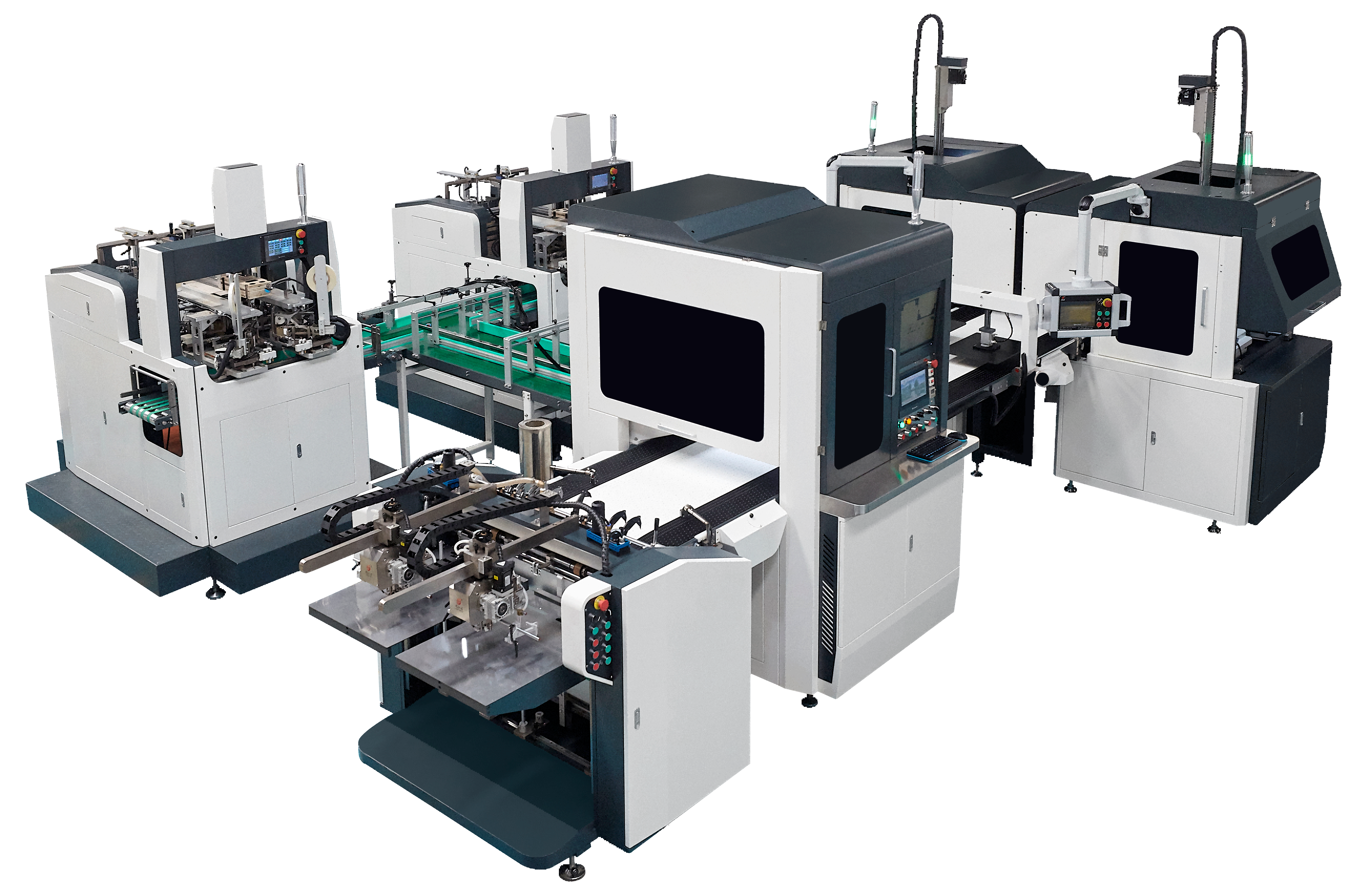

Enhance your cardboard lamination production process with our state-of-the-art Automatic Double Duty Rigid Box Making Machine. Specifically designed for manufacturers in need of efficient and versatile equipment, this cutting-edge machine combines advanced technology with precision engineering to streamline your production and deliver outstanding results.

| Type | LS-900A |

| Paper size(max) | L650xW400mm |

| Paper size(min) | L130xW120mm |

| Max cardboard size | / |

| Min cardboard size | / |

| Box size(Length) | L50-350mm |

| Box size(Width) | W50-250mm |

| Box size(Height) | H10-120mm |

| Working speed | 12-25(Pair)/min |

| Paper thickness | 100-350g/m2 |

| Paper stacking height | 540mm/100KG |

| Cardboard thickness | 0.8-5mm |

| Edge folding size | / |

| Turn in depth | 15-80mm |

| Motor power | 9kw/380V 3phase |

| Machine weight | 8kw |

| Air pressure | 30L/min |

| Machine dimension | L6378xW3860xH2200mm |

| Weight of machine | 2300kg |

Powered by Mitsubishi servo motors and PLC servo motors, this machine delivers exceptional performance and reliability. The inclusion of a high-precision YAMAHA robotic arm further enhances the efficiency and stability of box production. With a production capacity of 12-25 pairs of boxes per minute, this machine is capable of meeting the demands of large-scale orders. Additionally, its adjustable speed feature makes it suitable for smaller orders as well.

Key Features:

Dual Functionality: Our Automatic Double Duty Rigid Box Making Machine offers dual functionality, allowing you to laminate cardboard and manufacture rigid boxes in a single, seamless process. This versatile feature eliminates the need for multiple machines and optimizes your production line for enhanced efficiency and productivity.

High-Quality Lamination: Achieve impeccable cardboard lamination with this advanced machine. Its precision rollers and adjustable settings ensure uniform and smooth lamination, resulting in visually appealing and durable cardboard sheets. Experience consistent quality and excellent adhesion for your rigid box production.

Efficient Box Making: Seamlessly transition from cardboard lamination to rigid box production with ease. This machine automates the box-making process, from folding to gluing, ensuring precise and flawless box construction. Increase your production capacity and reduce manual labor, saving valuable time and resources.

Customizable Box Sizes: Cater to a wide range of packaging needs with the Automatic Double Duty Rigid Box Making Machine. It accommodates various box sizes and styles, allowing you to create customized packaging solutions tailored to your specific requirements. From small gift boxes to large display cases, this machine offers unparalleled flexibility.

User-Friendly Operation: Simplify your production process with the machine's user-friendly interface. The intuitive control panel and clear instructions make it easy for operators to navigate and operate the machine efficiently. Minimize training time and maximize productivity with this user-centric design.

Robust and Reliable: Built to withstand the demands of industrial production, our Automatic Double Duty Rigid Box Making Machine is constructed with high-quality materials and components. Its robust design ensures durability and long-term reliability, providing you with a dependable solution that delivers consistent results.

1. Paper loading part: Double feeding platform by separated control

2. Feeding system:Automatic cycle feeding by feeder

3. Belt adjustment system: non-stop belt adjustment

4. Gluing system: Integrated gluing guide groove, easy to clean

5. Paper feeding part: Servo-driven cam feeder effectively avoids double paper feeding.

6.computer control: Servo control digital quick size adjustment

8. Box positioning system: big size range positioning, various in application, single mode running available.

Second pressing to make the bottom of the box stick better

Adopt black and white belt for more color application

Robotic arm: High accuracy ± 0.1mm

Using double cameras to operate independently, high speed and clear photo taking.

Whether you manufacture gift boxes, jewelry boxes, or premium product packaging, our Automatic Multi-functional Rigid Box Making Machine caters to your needs, adding unique value and appeal to your products.

Contact us now to learn more about the Automatic Multi-functional Rigid Box Making Machine and let us assist you in creating exquisite rigid box covers!